Construction, utility work, mining, drilling; as long as man has been walking on two legs, he has been moving earth to reshape his environment and gain advantages from it. In truth, while many other animals may burrow into the ground it is only people who have the capacity to completely reshape their surroundings to suit their needs and garner the bounty that mother earth often has hidden deep within her crust.

The methods used haven’t always been gentle and for most of history excavation work required hard labour and more recently the use of heavy machinery. While more efficient than hand digging earth moving equipment only exacerbates many of the problems associated with manual excavating. It is time consuming, requires a large amount of space to operate in, destructive to the surrounding environment, generates a large amount of pollution and beyond these major concerns the very items that people were trying to be reached were often damaged by the tools and machinery that were being used to unearth them.

With modern methods of vacuum excavation, all of these issues are eliminated. Equipment can be stationed remotely so clutter within the worksite is minimised. Being highly targetable, vacuum excavation causes little to no damage outside of the pit itself and is one of the most efficient methods that can be used to move earth. Because all that is used is highly controllable water and air there is a minimum amount of danger that buried electrical works, piping, sensitive fiber-optic cables or workers will be harmed in any way.

What is vacuum excavation?

Vacuum Excavation is an earth removal process that doesn’t require the use of heavy equipment such as excavators, backhoes or loaders. It also eliminates the need for dump trucks and similar haulers. Digging is accomplished through the use of high-pressure water jets to break up soil, sand and rock creating a slurry which is then removed with a vacuum hose attached to a tanker truck where solids are separated from the water.

Advantages of vacuum excavation

Vacuum excavation offers many advantages over traditional digging methods. Being more precise, it causes less damage to areas surrounding the actual dig site and requires less back-fill. It also eliminates the risk of damaging existing features like water pipes, gas lines, power and fibre optic cables that would normally need to be hand dug around. This also reduces manpower requirements and lowers the risk of costly on the job injuries.

Hydro excavation requires far less equipment than other earth moving methods. Generally, a single truck is operating at any given time. Rather than having the actual digging equipment operating and a means of removing the diggings, the entire operation is contained in a single vehicle. Less equipment means less pollution which is good for the environment. The excavation unit can even be located some distance from the dig site making it possible to work in confined locations where other earth moving equipment would be unable to gain access.

Being a wet process vacuum excavation causes little dust helping to maintain a cleaner worksite and requiring less clean up. Perhaps best of all is the simple truth that vacuum excavation is, in most circumstances, the quickest, most efficient and cost-effective method of soil removal available.

How does vacuum excavation work?

The vacuum excavation process begins with a site assessment. One of the main points of using a Non-destructive digging process like hydro excavation is to deliver maximum results with minimum disturbance. This includes placing the vac truck where it will cause as little disruption to traffic or any other activities in the vicinity.

Once a location is chosen the truck will be parked and any needed hoses and vac lines will put into place. Depending on the location and preference of the client the sod may be removed and saved from the dig site for later replacement.

Once everything is prepared the vacuum and high-pressure pumps will be engaged. The vacuum is provided by either a positive displacement pump or fan system and is much like an industrial sized shop vac. The high-pressure or hydro pump is very similar to those used to wash cars or clean concrete.

Working at extreme velocities and with great force, the water turns the soil into a slurry or thin mud. The pressures used are high enough to dislodge rocks. The vacuum line then draws the mud and debris into the tank on the truck where most of the water is filtered out for reuse and the solids are captured for later disposal.

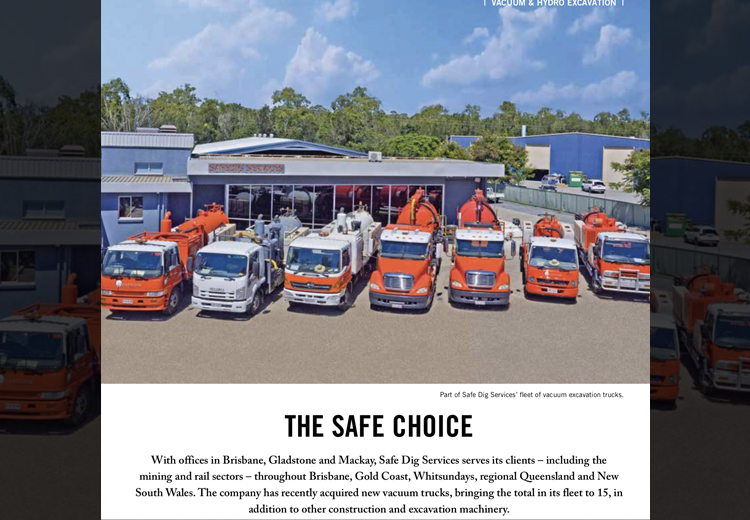

Hydro or vacuum excavation is the least intrusive, most cost effective and precise method of moving earth available. It is also the safest for both people and the environment. For more information on Non-destructive digging in Queensland including the Mackay, Gladstone and Brisbane areas, contact SafeDig Services today.

How does vacuum excavation work?

Construction, utility work, mining, drilling; as long as man has been walking on two legs, he has been moving earth to reshape his environment and gain advantages from it. In truth, while many other animals may burrow into the ground it is only people who have the capacity to completely reshape their surroundings to suit their needs and garner the bounty that mother earth often has hidden deep within her crust.

The methods used haven’t always been gentle and for most of history excavation work required hard labour and more recently the use of heavy machinery. While more efficient than hand digging earth moving equipment only exacerbates many of the problems associated with manual excavating. It is time consuming, requires a large amount of space to operate in, destructive to the surrounding environment, generates a large amount of pollution and beyond these major concerns the very items that people were trying to be reached were often damaged by the tools and machinery that were being used to unearth them.

With modern methods of vacuum excavation, all of these issues are eliminated. Equipment can be stationed remotely so clutter within the worksite is minimised. Being highly targetable, vacuum excavation causes little to no damage outside of the pit itself and is one of the most efficient methods that can be used to move earth. Because all that is used is highly controllable water and air there is a minimum amount of danger that buried electrical works, piping, sensitive fiber-optic cables or workers will be harmed in any way.

What is vacuum excavation?

Vacuum Excavation is an earth removal process that doesn’t require the use of heavy equipment such as excavators, backhoes or loaders. It also eliminates the need for dump trucks and similar haulers. Digging is accomplished through the use of high-pressure water jets to break up soil, sand and rock creating a slurry which is then removed with a vacuum hose attached to a tanker truck where solids are separated from the water.

Advantages of vacuum excavation

Vacuum excavation offers many advantages over traditional digging methods. Being more precise, it causes less damage to areas surrounding the actual dig site and requires less back-fill. It also eliminates the risk of damaging existing features like water pipes, gas lines, power and fibre optic cables that would normally need to be hand dug around. This also reduces manpower requirements and lowers the risk of costly on the job injuries.

Hydro excavation requires far less equipment than other earth moving methods. Generally, a single truck is operating at any given time. Rather than having the actual digging equipment operating and a means of removing the diggings, the entire operation is contained in a single vehicle. Less equipment means less pollution which is good for the environment. The excavation unit can even be located some distance from the dig site making it possible to work in confined locations where other earth moving equipment would be unable to gain access.

Being a wet process vacuum excavation causes little dust helping to maintain a cleaner worksite and requiring less clean up. Perhaps best of all is the simple truth that vacuum excavation is, in most circumstances, the quickest, most efficient and cost-effective method of soil removal available.

How does vacuum excavation work?

The vacuum excavation process begins with a site assessment. One of the main points of using a Non-destructive digging process like hydro excavation is to deliver maximum results with minimum disturbance. This includes placing the vac truck where it will cause as little disruption to traffic or any other activities in the vicinity.

Once a location is chosen the truck will be parked and any needed hoses and vac lines will put into place. Depending on the location and preference of the client the sod may be removed and saved from the dig site for later replacement.

Once everything is prepared the vacuum and high-pressure pumps will be engaged. The vacuum is provided by either a positive displacement pump or fan system and is much like an industrial sized shop vac. The high-pressure or hydro pump is very similar to those used to wash cars or clean concrete.

Working at extreme velocities and with great force, the water turns the soil into a slurry or thin mud. The pressures used are high enough to dislodge rocks. The vacuum line then draws the mud and debris into the tank on the truck where most of the water is filtered out for reuse and the solids are captured for later disposal.

Hydro or vacuum excavation is the least intrusive, most cost effective and precise method of moving earth available. It is also the safest for both people and the environment. For more information on Non-destructive digging in Queensland including the Mackay and Brisbane areas, contact SafeDig Services today.